Prefabrication

workshop

Our products:

- Pressure vessels compliant with Directive 2014/68/EU and ASME,

- Reactors,

- Mixers,

- Valve and Pump Systems,

- Pump and piping systems that are part of process plants,

- Heat exchangers,

- Steel structures such as platforms, stairs, balustrades,

- Complete SKID installations.

Welding technology:

- TIG, MAG,

- TIG orbital welding of pipelines,

- Automatic welding of tanks.

Assembly and welding of:

- Stainless steel structures,

- Stainless steel technological pipelines,

- Stainless steel process equipment,

- Stainless steel valves,

- Stainless steel process systems.

Qualitative testing services:

Visual inspection of welds with the use of endoscopes:

We use Olympus endoscopes as a way of checking the weld seam rims in places which are difficult to access (mainly pipes). Pictures and films from endoscopic checks are attached to the as-built documentation.

Spectroscope testing:

We use Brucker equipment to confirm the chemical composition and specify the grade of materials used. Tests are performed in accordance with relevant technological standards.

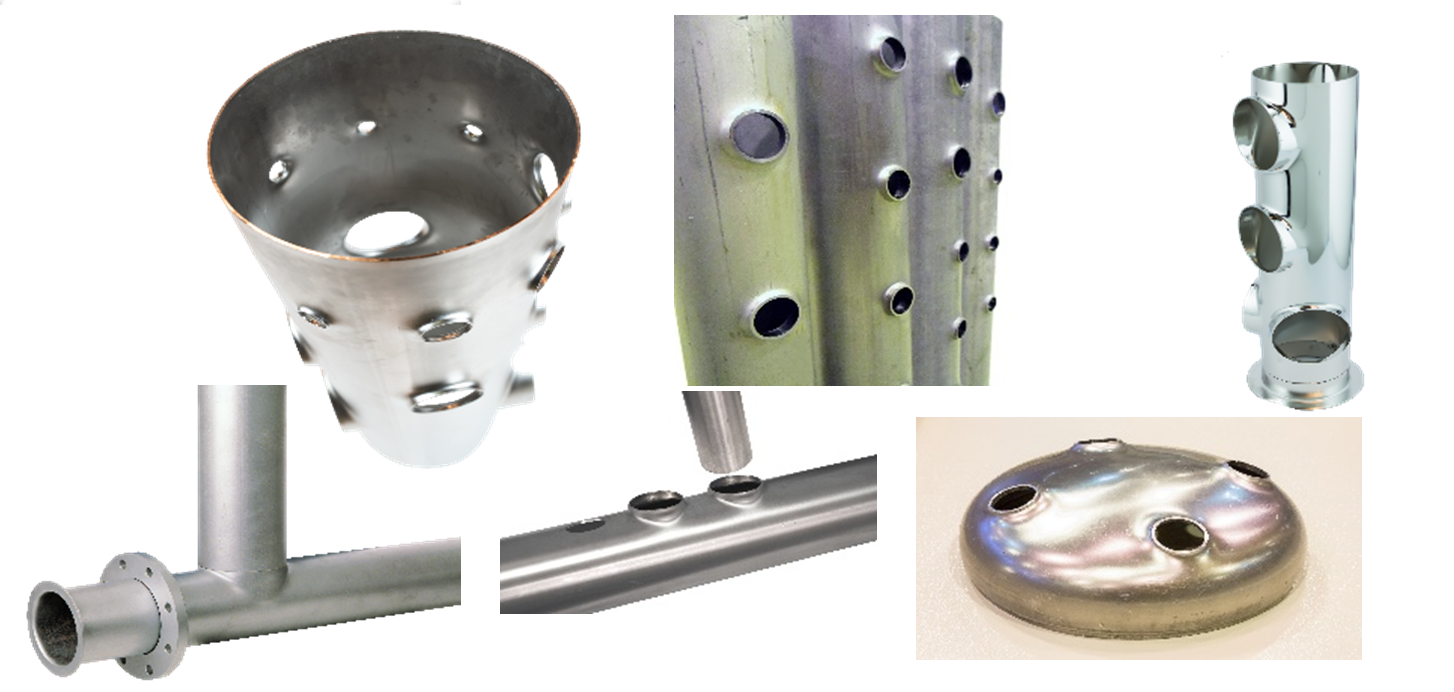

COLLARING MACHINE

for mechanically formed T-outlets up to SCH40 pipes

T-DRILL TEC-220 is a highly powerful collaring machine for up to SCH40 pipes. The TEC-220 forms mechanically extruded outlets directly on pipes with a maximum diameter up to DN1000 (40'') 1016 mm. The machine is suitable for branching all malleable materials (Steel, Stainless steel, Aluminum, Copper & Copper-Nickel).

The entire process from pilot hole milling to a complete, trimmed branch outlet of max. ⌀219,1mm (8”) can be performed on a single workstation in three automatic work cycles. Pilot hole milling and collaring are easily controlled by an operation panel.

Production plant area: 2700 m2

Storage areas:

- Indoor warehouse: 600 m2,

- Outdoor warehouse: 1 500 m2.

Warehouse management is carried out using an up-to-date management software.

Our capacity:

- Metal sheets approx. 160 T/year

- Pipelines approx. 40 thousand m/year

- Steel structures approx. 95 T/year

ISO standards and norms:

- Management systems: ISO9001:2015, SCC

- Manufacturing Certificates: EN1090 EXC3, ISO3834, AD 2000 Merkblatt, ASME, PED, UDT, TDT

Surface roughness tests:

We perform this testing using a device by Diavite.

Tests of paint layer thickness:

Measurements are carried out with a measuring device made by Metrison.

Chemical treatment:

Our chemical treatment station enables us to carry out etching, passivation and the process of steel washing.

We create quality documentation including:

- Welding documentation,

- NDT,

- As-built documentation “copy in red”,

- Material attestations,

- CE marking,

- Declarations of conformity.

Our partners in the electrical, control and automation industries:

We work with partner entities in the field of electrical assembly, automation and control, including installations assembled by us and their commissioning.